In today’s industrial landscape, ensuring security isn’t just about guarding entry points—it’s about securing processes, assets, and people with intelligence. That’s where the Advanced Access Control system steps in. For manufacturing plants, this system offers more than just card-based entry—they deliver operational safety, traceability, and compliance. An industry report by Markets and Data reveals significant growth in the global access control and authentication market. Starting at $13.2 billion in 2022, it’s set to expand to $26.1 billion by 2030, reflecting a robust 8.9% CAGR for the period between 2023 and 2030. In fact, a study by IBM shows that internal threats account for nearly 60% of manufacturing-related data breaches, making identity-based access control a critical need.

Why Traditional Access Control Isn’t Enough

Manufacturing plants operate with high-value assets, dangerous machinery, and round-the-clock shifts. Legacy access system—limited to basic RFID or PINs—fails to monitor who, where, and when with precision. The traditional system lacks real-time visibility, contextual intelligence, and scalability to meet these evolving needs. A breach here isn’t just a loss—it could halt production or trigger a safety hazard. Most importantly, they can’t adapt dynamically to shifts, roles, or emergency overrides. In an era where cyber-physical threats are rising and compliance audits are tighter, traditional access just isn’t equipped to protect modern manufacturing setups.

Types of Advanced Access Control system

Modern manufacturing facilities are adopting multiple types of advanced access control system, such as:

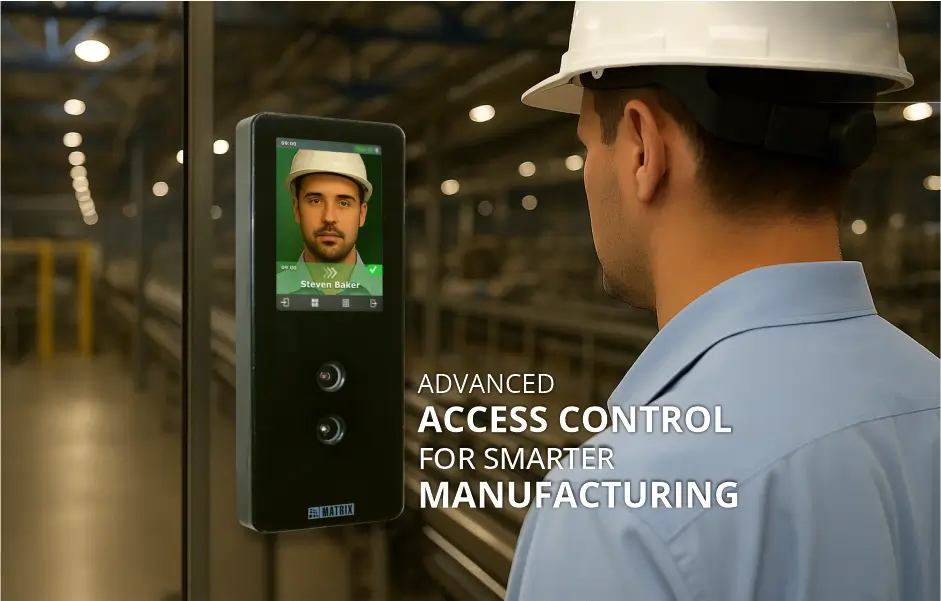

- Biometric Authentication: Fingerprint, iris-based, or facial access control system eliminates the risk of credential sharing. According to the Lift HCM article “Slash Time Theft: Choosing Between Biometric and Digital Time Clocks”, for a 100-employee company, a biometric system typically eliminates an average of 2.5 hours of time theft per employee per month, translating to approximately $45,000 in annual savings based on average wage calculations.

- Multi-factor Authentication (MFA): Combining credentials (card and biometric access control system) to strengthen entry authorization. According to CISA (Cybersecurity and Infrastructure Agency), the use of MFA makes users 99% less likely to be hacked!

- Mobile-based Access: Access through secure mobile apps enhances user convenience and hygiene. The global mobile access control system market size is predicted to be valued at $1,638,455.4 thousand by 2032, surging from $228,690.0 thousand in 2022, at a noteworthy CAGR of 22.4%, as noted by the research dive, a market research firm.

- Role-Based Access: Access is customized based on job function or hierarchy to critical zones. According to a report by Tata Communications, Role-Based Access Control (RBAC) is a key practice that limits the potential effect of insider threats by allowing workers the right to do their duties.

How Matrix Empowers Manufacturing Security

For manufacturing entities seeking to enhance industrial safety and operational excellence, a robust and advanced access control system is paramount. Solutions such as those offered by Matrix provide capabilities like modular, role-based, time and zone-based, and device-based user access control policies, real-time alerts, and tamper detection mechanisms. These features are designed to help streamline operations, ensure compliance with regulatory standards, and mitigate security risks, ultimately contributing to optimized efficiency, enhanced safety, and asset protection within a dynamic industrial landscape.

Ready to embrace a future where industrial safety and operational excellence harmoniously converge? Discover how advanced access control solutions can enlighten your manufacturing environment with unparalleled security, seamless efficiency, and complete peace of mind.